M9R

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift.

- Remove:

- the engine cover,

- the engine undertray.

- Drain the engine cooling circuit.

- Remove:

- the clips from the air inlet sleeve,

- the air intake sleeve on the air filter unit,

- the battery,

- the battery tray.

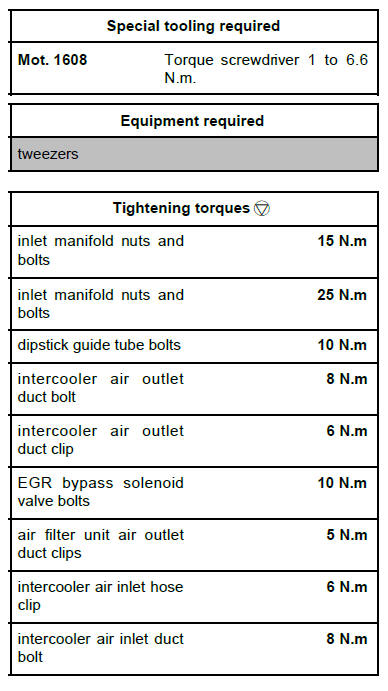

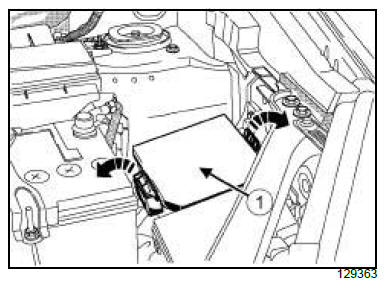

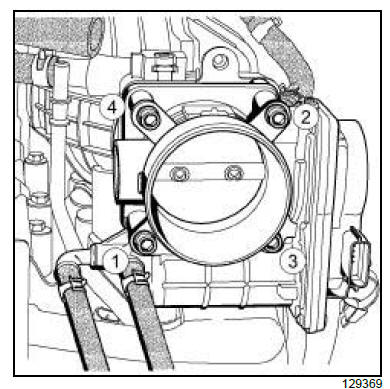

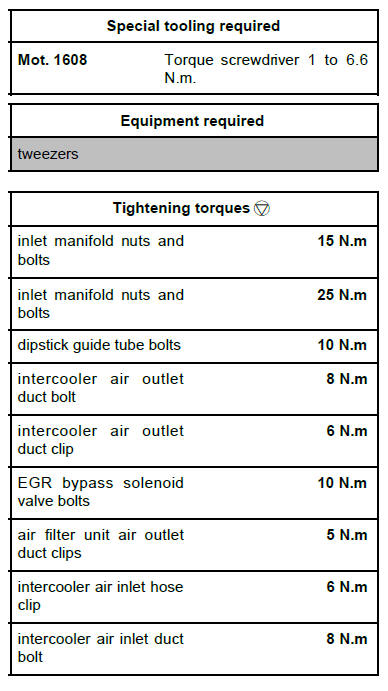

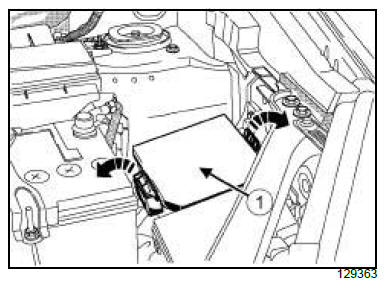

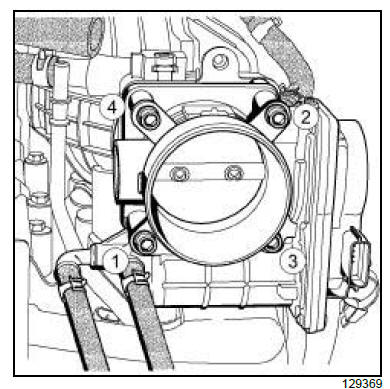

- Turn the clip (1) on the intercooler air inlet duct.

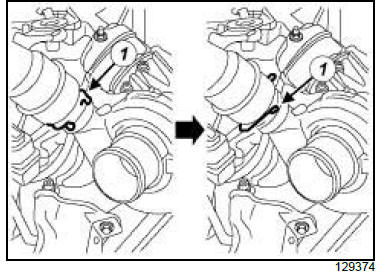

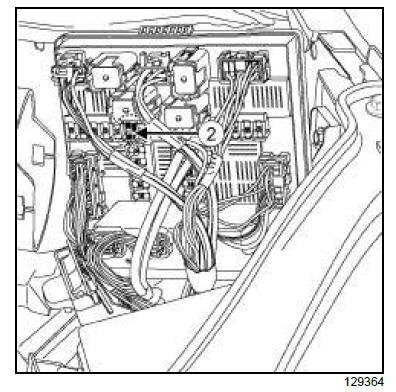

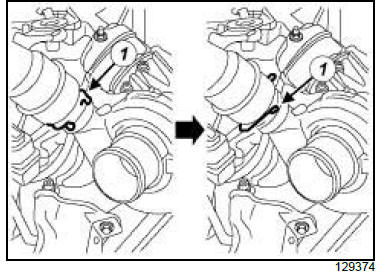

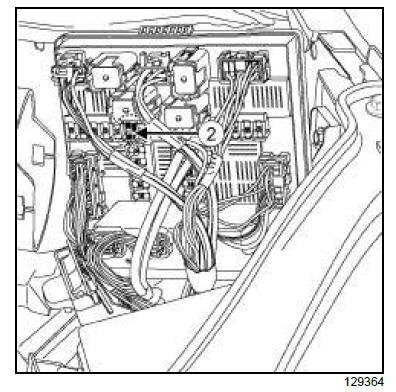

- Remove the intercooler air inlet duct bolt (2) from the

fuel pipe support.

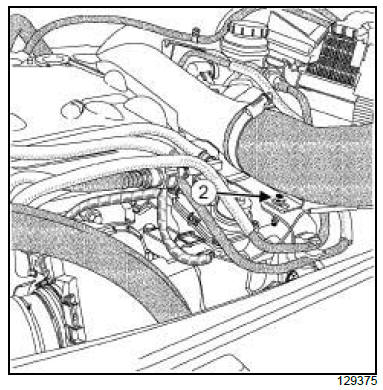

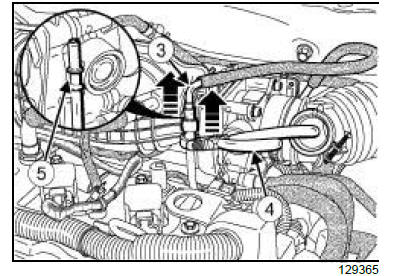

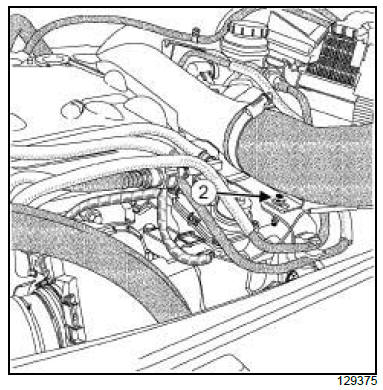

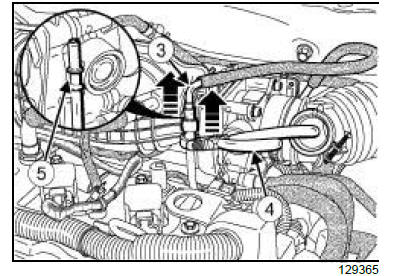

- Loosen the clip (3) on the intercooler air inlet duct.

- Remove:

- the air inlet duct assembly (4) from the intercooler,

- the air filter unit.

- Loosen the air filter unit air outlet duct clip on the turbocharger.

- Disconnect:

- the oil vapour rebreathing pipe from the oil separator,

- the air filter unit air outlet duct from the turbocharger.

- Fit a blanking plug in the opening of the oil separator.

- Remove:

- the windscreen wiper arms

- the scuttle half-grille

- the windscreen wiper mechanism

- the scoop under the scuttle panel grille

- the water chamber

- the exhaust gas recirculation rigid pipe between

the exhaust manifold and the exhaust gas cooler.

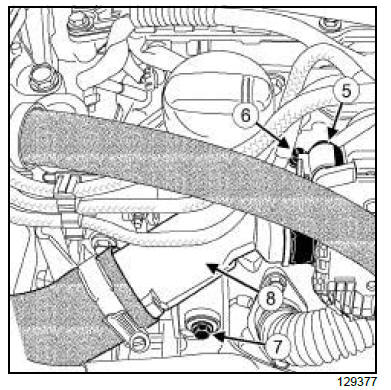

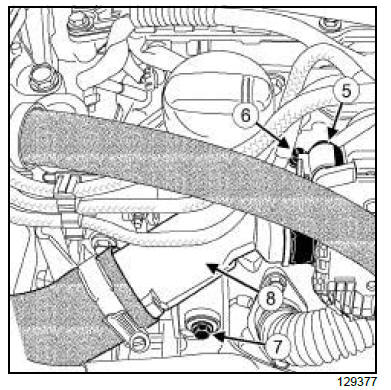

- Disconnect the connector from the damper valve

wiring (5) .

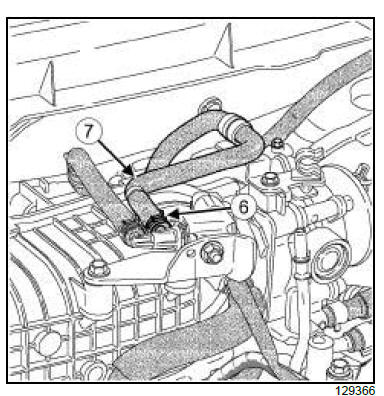

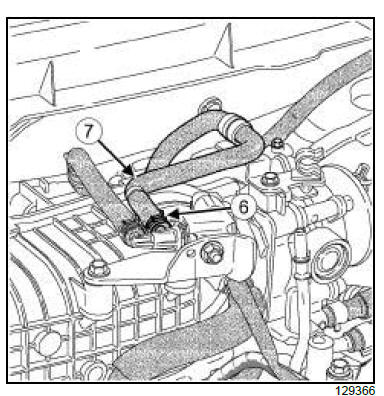

- Loosen the clip (6) on the intercooler air inlet duct.

- Remove the bolt (7) from the intercooler air outlet

duct.

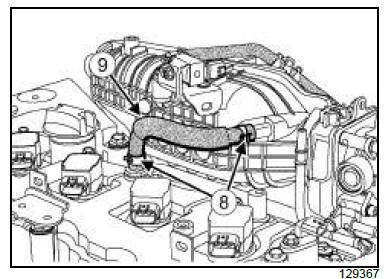

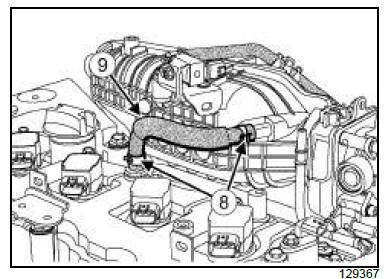

- Disconnect the intercooler air outlet duct (8) from the

damper valve.

- Move the intercooler air outlet duct to one side.

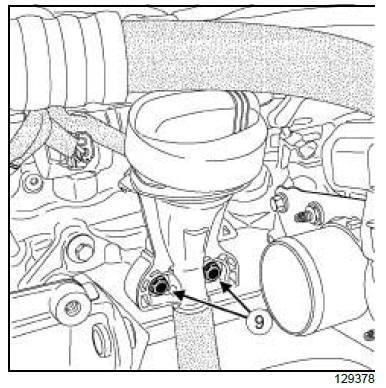

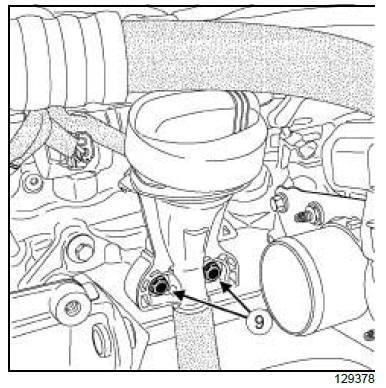

- Remove:

- the dipstick guide tube bolts (9) ,

- the dipstick guide tube.

- Plug the opening of the dipstick guide tube on the

cylinder block.

- Remove the damper valve.

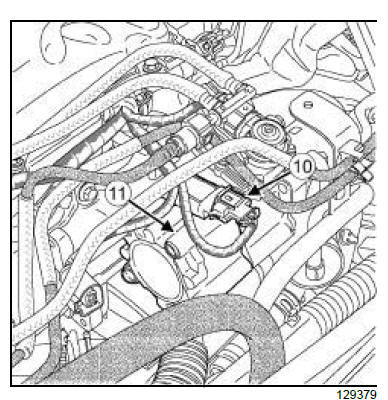

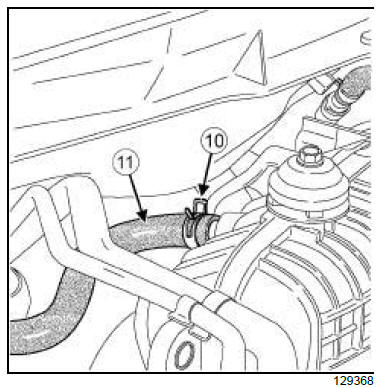

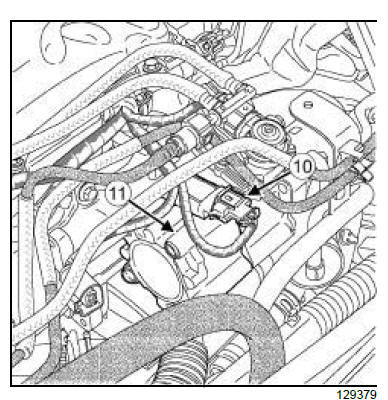

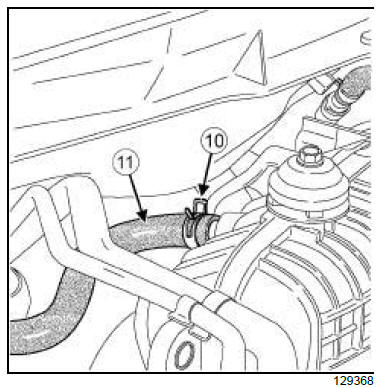

- Disconnect the connector (10) from the turbocharger

pressure sensor.

- Remove:

- the turbocharger pressure sensor housing (11) ,

- the exhaust gas recirculation rigid pipe between

the exhaust gas recirculation solenoid valve and

the exhaust gas cooler,

- the EGR solenoid valve,

- the starter ,

- the intercooler,

- the front right-hand wheel,

- the front right-hand wheel arch liner,

- the accessories belt,

- the alternator,

- the multifunction support.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

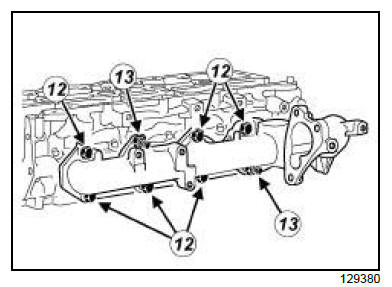

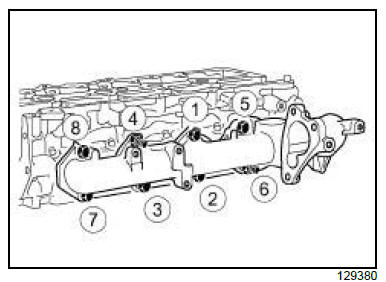

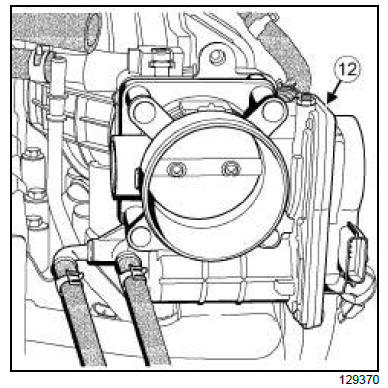

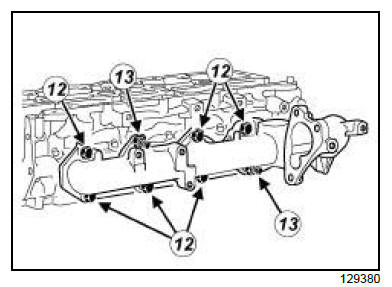

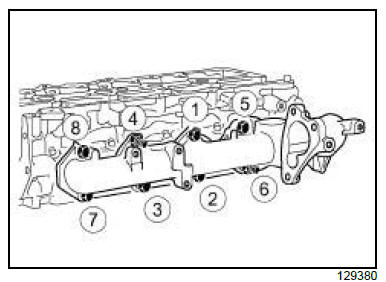

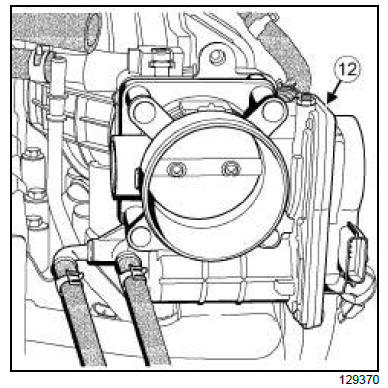

- Remove:

- the intake distributor bolts (12) ,

- the intake distributor nuts (13) ,

- the inlet manifold,

- the inlet manifold gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

| WARNING

The joint faces must be clean, dry and free from

grease (avoid finger marks). |

- Clean:

- the cylinder head joint face,

- the intake distributor joint face,

- the exhaust gas recirculation rigid pipe joint faces,

- the turbocharger pressure sensor housing joint faces,

- the damper valve seal face.

- Always replace:

- the inlet manifold gasket,

- the exhaust gas recirculation rigid pipe between

the exhaust manifold and the exhaust gas cooler,

- the exhaust gas recirculation rigid pipe seal on the

exhaust manifold,

- the exhaust gas recirculation rigid pipe seals,

- the exhaust gas recirculation rigid pipe clip,

- the rigid exhaust gas recirculation pipe bolts,

- the coolant outlet unit seal,

- the gasket between the intake distributor and the

EGR solenoid valve.

- the seal between the turbocharger pressure sensor

housing and the EGR solenoid valve,

- the seal between the damper valve and the turbocharger

pressure sensor housing,

- the intercooler air inlet duct seal.

II - REFITTING OPERATION FOR PART

CONCERNED

- Refit:

- the new intake distributor seal,

- the inlet manifold,

- the inlet manifold nuts and bolts.

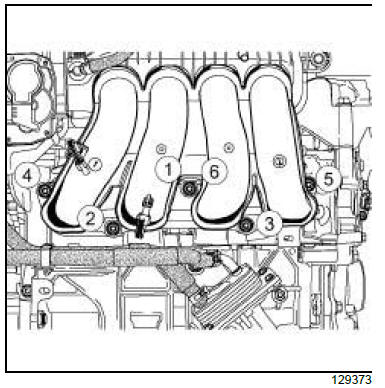

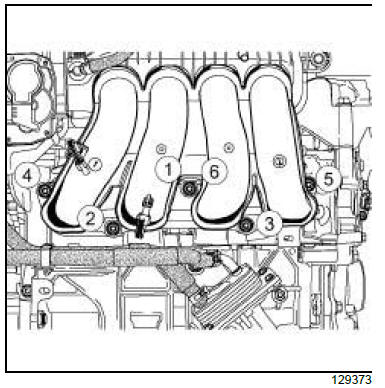

- Pretighten to torque and in order the inlet manifold

nuts and bolts (15 N.m).

- Torque tighten in order the inlet manifold nuts and

bolts (25 N.m).

III - FINAL OPERATION.

- Refit:

- the multifunction support

- the alternator

- the accessories belt

- the front right-hand wheel arch liner

- the front right-hand wheel

- the intercooler

- the starter

- the new seal between the EGR solenoid valve and

the intake distributor

- the EGR solenoid valve

- the new exhaust gas recirculation rigid pipe seals

- the exhaust gas recirculation rigid pipe between

the exhaust gas recirculation solenoid valve and

the exhaust gas cooler

- the new seal between the turbocharger pressure

sensor housing and the EGR solenoid valve

- the turbocharger pressure sensor housing.

- Connect the turbocharger pressure sensor connector.

- Refit:

- the seal between the damper valve and the turbocharger

pressure sensor housing,

- the damper valve.

- Remove the plug from the opening of the dipstick

guide tube on the cylinder block.

- Torque tighten the dipstick guide tube bolts (10

N.m).

- Connect the intercooler air outlet duct to the damper

valve.

- Refit the intercooler air outlet duct bolt.

- Torque tighten:

- the intercooler air outlet duct bolt (8 N.m),

- the intercooler air outlet duct clip (6 N.m) using

the tool (Mot. 1608).

- Connect the damper valve wiring connector.

- Refit:

- the exhaust gas recirculation rigid pipe seal on the

exhaust manifold

- the exhaust gas recirculation rigid pipe between

the exhaust manifold and the exhaust gas cooler

- the coolant outlet unit seal

- the water chamber

- the water chamber hoses and pipes

- Fit the EGR bypass solenoid valve.

- Refit the EGR bypass solenoid valve bolts.

- Torque tighten the EGR bypass solenoid valve

bolts (10 N.m).

- Connect:

- the vacuum hoses on the EGR bypass solenoid

valve and on the exhaust gas cooler,

- the EGR bypass solenoid valve connector.

- Refit the air filter unit.

- Connect the air filter unit air outlet duct to the turbocharger

and to the air filter unit.

- Torque tighten the air filter unit air outlet duct

clips (5 N.m) using the tool (Mot. 1608).

- Remove the blanking plug from the opening of the oil

separator.

- Connect the oil vapour rebreathing hose to the oil

separator.

- Fit the intercooler air inlet duct assembly onto the intercooler

air inlet pipe.

- Torque tighten the intercooler air inlet hose clip (6

N.m) using the tool (Mot. 1608).

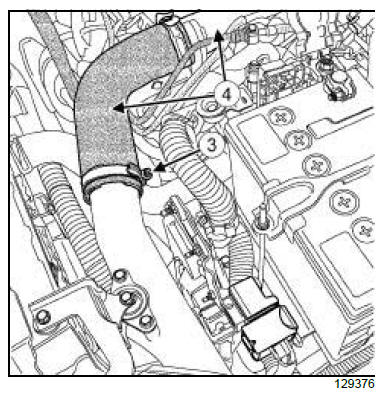

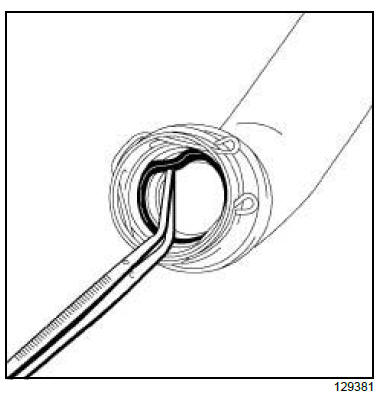

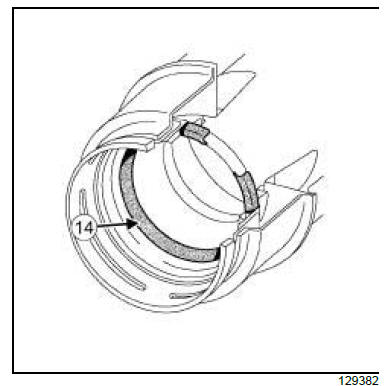

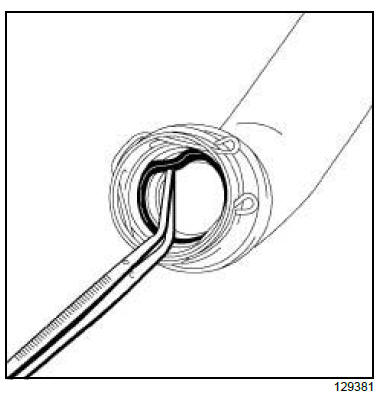

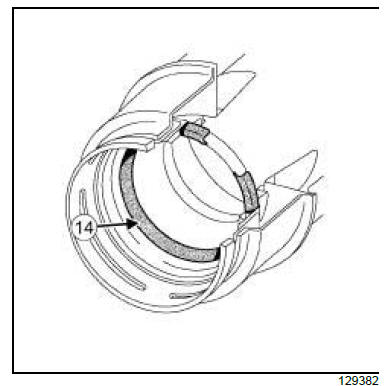

- Remove the intercooler air inlet duct seal using a

tweezers.

| Note:

Check whether the intercooler air inlet duct seal

(14) is correctly positioned. |

- Refit the new intercooler air inlet duct seal.

- Turn the intercooler air inlet duct to fit the clip in its

housing.

- Clip the intercooler air inlet duct onto the turbocharger.

- Refit the intercooler air inlet duct bolt to the fuel pipe

support.

- Torque tighten the intercooler air inlet duct bolt (8

N.m).

- Refit:

- the battery tray

- the battery

- the scoop under the scuttle panel grille

- the windscreen wiper mechanism

- the scuttle half-grille

- the windscreen wiper arms

- the air intake sleeve on the air filter unit

- the clips of the air inlet sleeve.

- Fill the engine cooling system .

- Bleed the engine cooling system .

- Refit:

- the engine undertray,

- the engine cover.

2TR

| IMPORTANT

Wear protective gloves during the operation. |

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift.

| IMPORTANT

To prevent the vehicle from falling, lash it to the

vehicle lift using a strap. |

- Remove the engine cover.

- Remove the air inlet sleeve.

- Disconnect the cover (1) from the Protection and

Switching Unit.

- Remove the fuse (2) of the fuel pump(F13) (15A).

- Release the fuel pressure in the fuel pipe after starting

the engine.

| Note:

After switching the engine off, start it again two or

three times to fully relieve the fuel pressure. |

- Remove:

- the battery

- the battery tray

- the air filter unit

- the engine cover

- the air resonator located on the rocker cover

- the air inlet duct.

- Remove the plug of the fuel supply union.

IMPORTANT

During this operation, be sure to:

- refrain from smoking or bringing red hot objects

close to the working area,

- be careful of fuel splashes when disconnecting

the union.

|

- Disconnect the quick-release union (3) using the tool

(Mot. 1869) (4) as illustrated.

| Note:

Insert the tool (Mot. 1869) (4) into the second

retaining part (5) . |

- Remove the petrol vapour rebreathing pipe clip (6) .

- Disconnect the petrol vapour rebreathing pipe (7) .

- Remove the clips (8) of the oil vapour rebreathing

hose.

- Disconnect the oil vapour rebreathing hose (9) .

- Remove the clip (10) from the vacuum pipe of the

brake servo.

- Disconnect the vacuum pipe (11) from the brake servo.

- Remove:

- the windscreen wiper arms

- the scuttle panel half-grille

- the windscreen wiper mechanism

- the scoop under the scuttle panel grille.

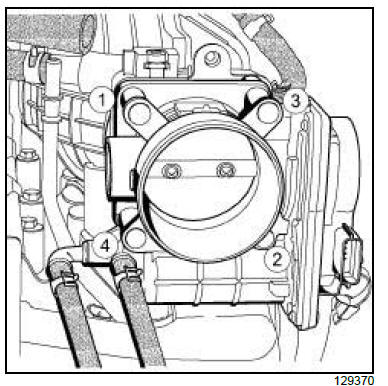

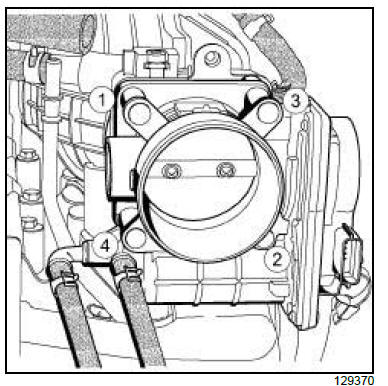

- Disconnect the motorised throttle valve connector.

- Remove:

- in order the motorised throttle valve bolts,

- the motorised throttle valve without disconnecting

the coolant pipes.

- Move aside the throttle valve (12) .

- Remove:

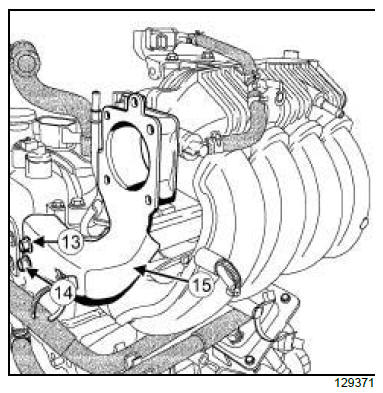

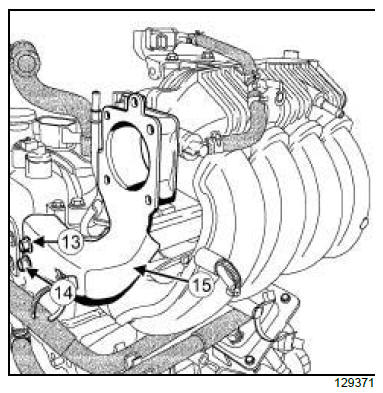

- the intake distributor support bolts (13) and (14) ,

- the intake distributor support (15) ,

- the seal.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

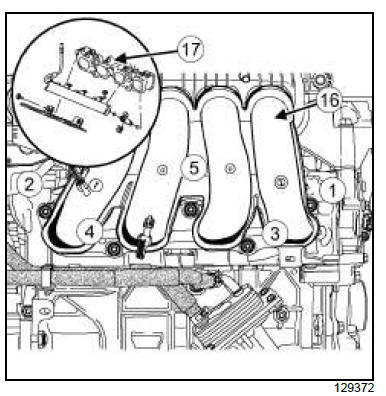

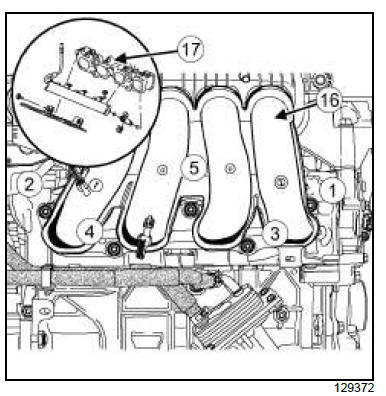

- Remove:

- in order, the intake distributor bolts and nuts,

- the inlet manifold (16) ,

- the intake distributor seal,

- the intake distributor adapter (17) ,

- the intake distributor adapter seal.

| Note:

The engine must remain covered to prevent

impurities from entering inside. |

REFITTING

I - REFITTING PREPARATION OPERATION

- Always replace:

- the intake distributor seal,

- the intake distributor adapter seal,

- the motorised throttle valve seal.

II - REFITTING OPERATION FOR PART

CONCERNED

- Refit:

- the new intake distributor adapter seal,

- the intake distributor adapter,

- the new intake distributor seal,

- the inlet manifold,

- the intake distributor nuts and bolts.

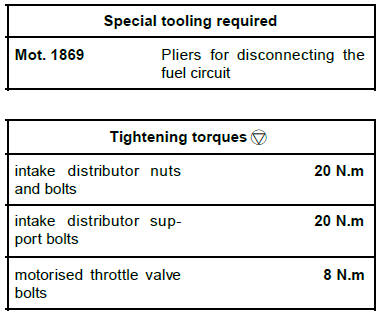

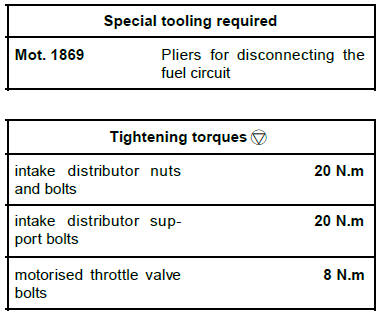

- Torque tighten in order the intake distributor nuts

and bolts (20 N.m).

| Note:

Mark (6) indicates retightening of the bolt to a

torque of 20 N.m. |

III - FINAL OPERATION

- Refit:

- the new intake distributor support seal,

- the intake distributor support,

- the intake distributor support bolts.

- Torque tighten the intake distributor support bolts

(20 N.m).

- Refit:

- the new motorised throttle valve seal,

- the motorised throttle valve bolts.

- Torque tighten in order the motorised throttle

valve bolts (8 N.m).

- Connect the motorised throttle valve connector.

- Refit:

- the scoop under the scuttle panel grille

- the windscreen wiper mechanism

- the scuttle panel half-grille

- the windscreen wiper arms.

- Connect the brake servo vacuum pipe.

- Refit the clip of the vacuum pipe of the brake servo.

- Connect the oil vapour rebreathing hoses.

- Refit the clips of the oil vapour rebreathing hose.

- Disconnect the petrol vapour rebreathing pipe.

- Refit the petrol vapour rebreathing pipe clip.

- Connect the quick-release union of the fuel supply.

| Note:

Check the condition of the quick-release union

connection again. |

- Remove the fuel supply union plug.

- Refit:

- the air inlet duct

- the air resonator located on the rocker cover

- the engine cover

- the air filter unit

- the battery tray

- the battery

- the fuel pump fuse

- the Protection and Switching Unit cover.

- Refit the air intake sleeve.

|