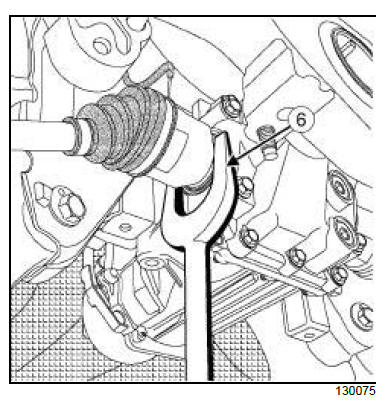

REMOVAL

I - REMOVAL PREPARATION OPERATION

- Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

| IMPORTANT

To prevent the vehicle from falling, lash it to the

vehicle lift using a strap. |

- Drain the oil from the rear final drive (see 26A, Rear

axle, Rear axle oil: Draining - Filling, page 26A-

11) .

- Remove the rear wheels on the side concerned (see

Wheel: Removal - Refitting) (35A, Wheels and tyres).

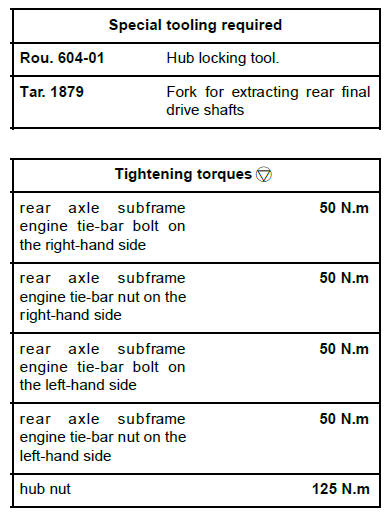

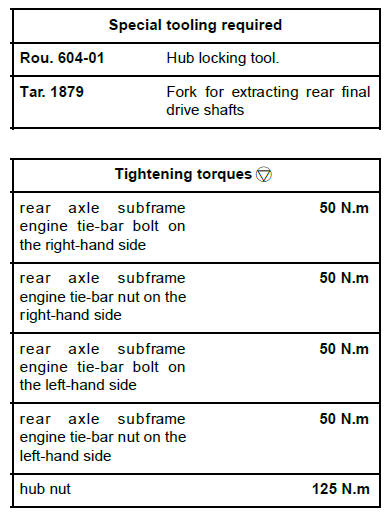

- Remove:

- the cotter pin (1) ,

- the nut (2) from the hub carrier using the tool (Rou.604-01).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Rear right-hand driveshaft

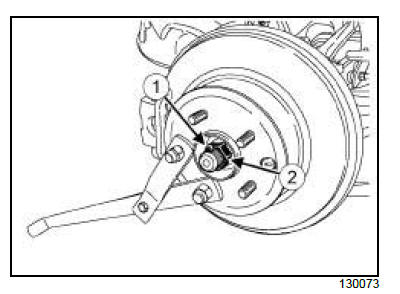

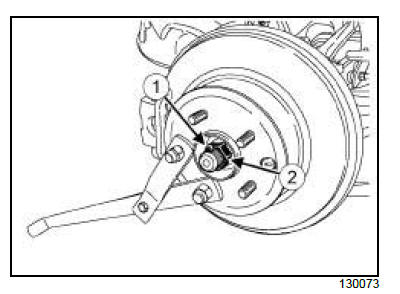

- Remove:

- the engine tie-bar bolt (3) from the rear axle subframe

on the right-hand side,

- the engine tie-bar nut (4) from the rear axle subframe

on the right-hand side,

- the engine tie-bar (5) from the rear axle subframe

on the right-hand side.

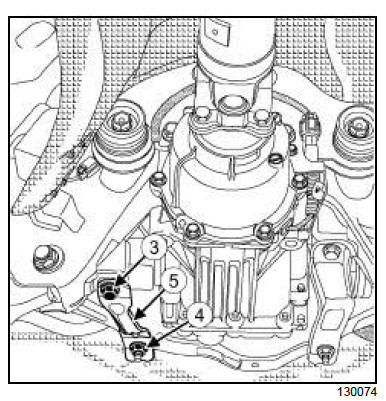

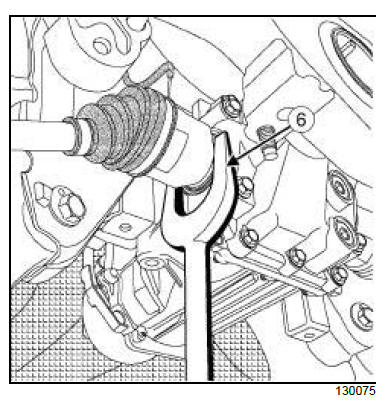

- Disconnect the rear right-hand driveshaft using the

tool (Tar. 1879) (6) .

- Remove the rear right-hand suspension spring (see

Rear suspension spring: Removal - Refitting)

(33A, Rear axle components).

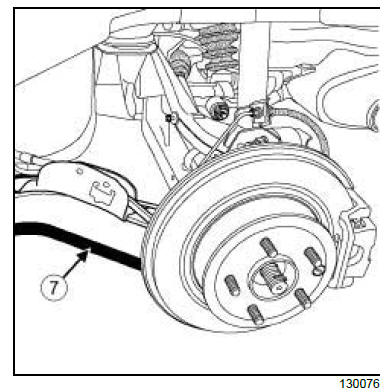

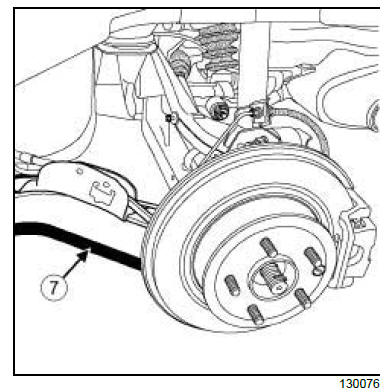

- Move aside the rear stub axle carrier (7) .

- Remove the rear right-hand driveshaft.

2 - Rear left-hand driveshaft

- Remove:

- the silencer (see Silencer: Removal - Refitting)

(19B, Exhaust).

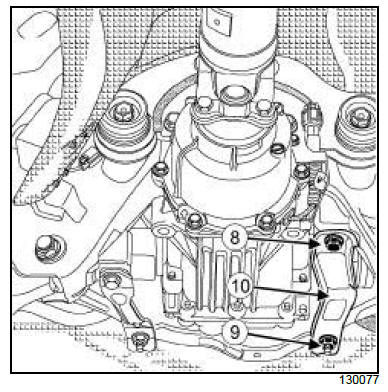

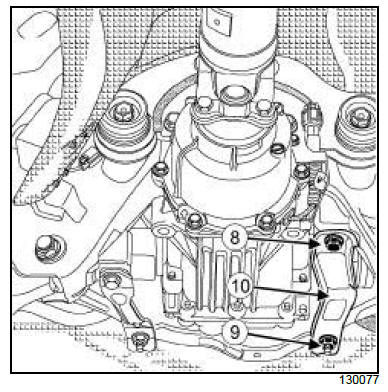

- the engine tie-bar bolt (8) from the rear axle subframe

on the left-hand side,

- the engine tie-bar nut (9) from the rear axle subframe

on the left-hand side,

- the engine tie-bar (10) from the rear axle subframe

on the left-hand side.

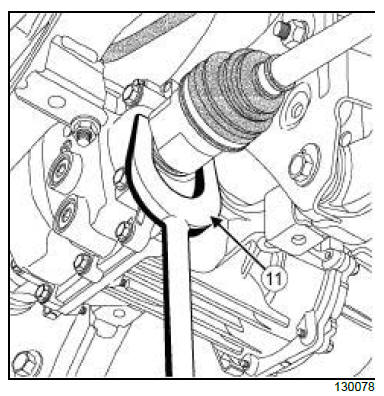

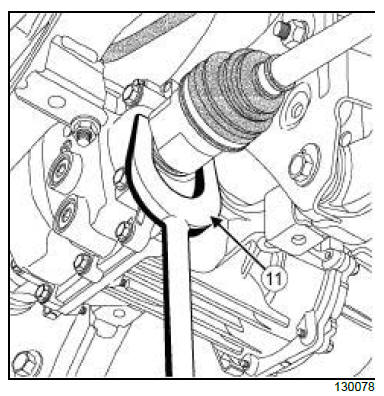

- Disconnect the rear left-hand driveshaft using the

tool (Tar. 1879) (11) .

- Remove the rear left-hand suspension spring (see

Rear suspension spring: Removal - Refitting)

(33A, Rear axle components).

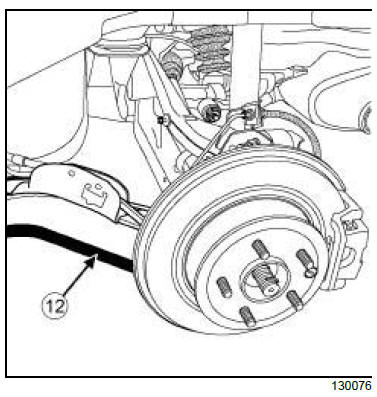

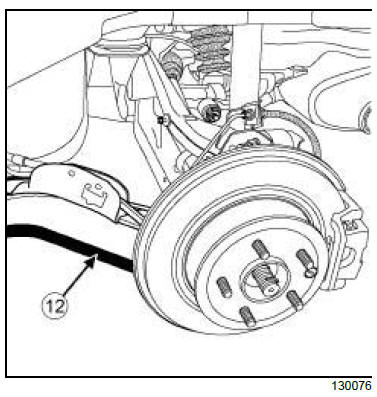

- Move aside the rear stub axle carrier (12) .

- Remove the rear left-hand driveshaft.

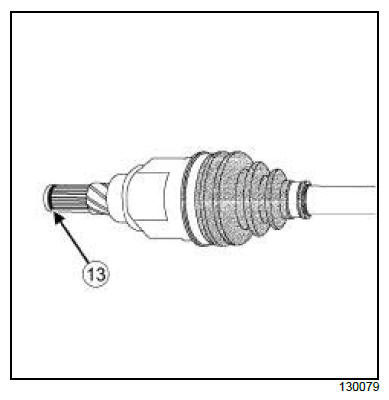

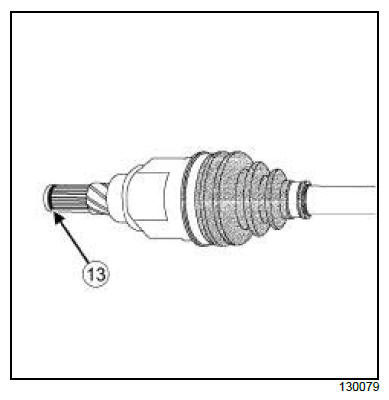

- Remove the rear left-hand driveshaft locking ring

(13) .

6-SPEED MANUAL GEARBOX

- Remove the differential output seal on the right-hand

side (see 21A, Manual gearbox, Differential output

seal: Removal - Refitting, page 21A-7) .

FK0 or FK8, and 6-SPEED AUTOMATIC GEARBOX

- Remove the differential output seal on the right-hand

side (see 23A, Automatic gearbox, Differential

output seal: Removal - Refitting, page 23A-17) .

REFITTING

I - REFITTING PREPARATION OPERATION

- Always replace:

- the rear left-hand driveshaft locking ring,

- the differential output seal,

- the cotter pin.

- Refit the new rear driveshaft locking ring.

6-SPEED MANUAL GEARBOX

- Refit the differential output seal on the right-hand

side (see 21A, Manual gearbox, Differential output

seal: Removal - Refitting, page 21A-7) .

FK0 or FK8, and 6-SPEED AUTOMATIC GEARBOX

- Refit the differential output seal on the right-hand

side (see 23A, Automatic gearbox, Differential

output seal: Removal - Refitting, page 23A-17) .

II - REFITTING OPERATION FOR PART

CONCERNED

1 - Rear right-hand driveshaft

- Refit:

- the rear right-hand driveshaft,

- the engine tie-bar on the rear axle subframe on the

right-hand side,

- the engine tie-bar bolt on the rear axle subframe on

the right-hand side,

- the engine tie-bar nut on the rear axle subframe on

the right-hand side

- Torque tighten:

- the rear axle subframe engine tie-bar bolt on the

right-hand side (50 N.m),

- the rear axle subframe engine tie-bar nut on the

right-hand side (50 N.m).

- Refit the rear right-hand suspension spring (see

Rear suspension spring: Removal - Refitting)

(33A, Rear axle components).

2 - Rear left-hand driveshaft

- Refit:

- the rear left-hand driveshaft,

- the engine tie-bar on the rear axle subframe on the

left-hand side,

- the engine tie-bar bolt on the rear axle subframe on

the left-hand side,

- the engine tie-bar nut on the rear axle subframe on

the left-hand side.

- Torque tighten:

- the rear axle subframe engine tie-bar bolt on the

left-hand side (50 N.m),

- the rear axle subframe engine tie-bar nut on the

left-hand side (50 N.m).

- Refit:

- the rear left-hand suspension spring (see Rear

suspension spring: Removal - Refitting) (33A,

Rear axle components).

- the silencer (see Silencer: Removal - Refitting)

(19B, Exhaust).

III - FINAL OPERATION.

- Refit the hub nut on the side concerned.

- Torque tighten the hub nut (125 N.m) using the tool

(Rou. 604-01) on the side concerned.

- Refit:

- the new cotter pin,

- the wheel on the side concerned (see Wheel: Removal

- Refitting) (35A, Wheels and tyres).

- Fill the rear final drive (see 26A, Rear axle, Rear

axle oil: Draining - Filling, page 26A-11)

DISCHARGE LAMPS

- Adjust:

- the headlights (see Headlight: Adjustment) (80B,

Headlights).

- the headlight beam adjustment rear sensor (see

Fault Finding - Programming) (80C, Discharge

bulbs).

- Adjust:

- the wheel geometry (see Rear axle system: Adjustment)

(30A, General information).

- the neutral position of the steering wheel sensor

(see Fault finding - Programming) (80B, Headlights).

|