| IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and operation

recommendations before carrying out any

repair (see 62A, Air conditioning, Air conditioning:

Precautions for repair, page 62A-1) . |

Fault finding for detecting leaks:

| Component |

Detection area |

Part to be replaced after

first check |

Part to be replaced after

filling and second check |

| Condenser |

Inlet or outlet |

Pipe |

Condenser |

| Evaporator |

Connection flange |

Pipe |

Connection flange and/or

evaporator |

| Compressor |

Inlet or outlet |

Pipes |

Compressor |

I - ELECTRONIC DETECTORS

| Note:

Check for leaks using the electronic detector first

before using the trace detector. |

- This device measures variations in the quantity of

refrigerant in the air and beeps accordingly.

- The device must be initialised before checking.

To do this:

- immobilise the device,

- calibrate the device in the engine compartment,

- do not start the engine.

- This point is then used as standard for detecting the

contamination rate.

This device is highly sensitive: during the detection

process, only follow the line of the circuit as closely

as possible to limit variations caused by other gases.

This device only detects relatively substantial leaks.

| Note:

Make sure that the sensor at the end of the rod is

extremely clean and in good condition. |

II - TRACE DETECTORS

| WARNING

After injecting dye into the refrigerant, be sure to

indicate this on a label (supplied with the dye

capsule), and the date of the operation.

Position the label so it is visible near to the cold

loop filler valve. |

- Detecting leaks using a tracer involves adding a dye

to the refrigerant, and locating the points of loss

using an ultraviolet light.

| Note:

The procedure described must be observed. |

| Note:

Use this leak detection method as a last resort

for leaks that cannot be located. |

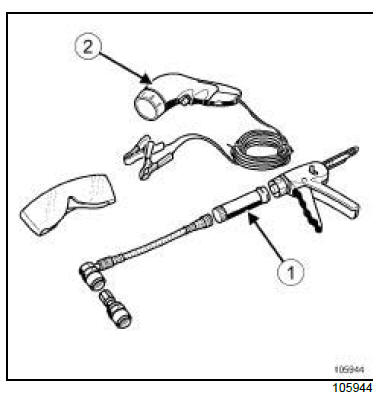

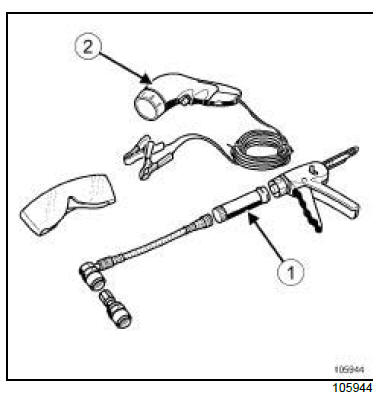

- The procedure for detecting refrigerant leaks uses a

dye which is available as a single-use capsule (1) :

traces of fluid are detected using an ultraviolet lamp

(2) .

- The dye remains in the air conditioning system.

- It is possible to check the status of the cold loop

using the ultraviolet lamp, without injecting the dye

again.

| WARNING

To avoid damaging the cold loop components

(corrosions, etc.), do not use dye if the traces

reveal that some product has already been injected. |

- If there is nothing to indicate that dye has been used

previously (label, etc.):

- position a cloth,

- release a small jet of refrigerant through the two

valves,

- light up the valve interior using the ultraviolet lamp,

- check for fluorescent traces.

- Add a dose of detection dye if there are no fluorescent

traces or label.

- Affix a label.

- Record the date when the dye was added.

1 - Injecting dye into the circuit

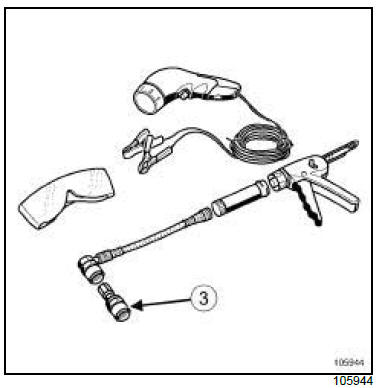

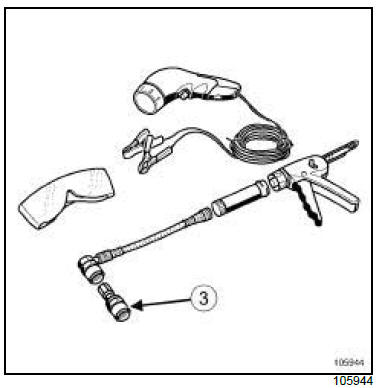

- For vehicles with a single valve, set up the dye injection

system on the low pressure valve by following

the circulation direction of the product and using the

union (3) .

- Inject the dye into the circuit.

- Run the air conditioning system for approximately 15

minutes.

2 - Leak detection procedure

- Carry out an initial check (with the engine stopped)

by sweeping the circuit with an ultraviolet light.

| Note:

Use an adjustable mirror wherever access is difficult. |

- If no leak is apparent:

- carefully clean the coolant circuit on the outside,

- run the air conditioning system until the leak is detected

(failing this, check the condition of the evaporator).

| WARNING

After injecting dye into the refrigerant, be sure to

indicate this on a label (supplied with the dye

capsule), and the date of the operation.

Position the label so it is visible near to the cold

loop filler valve. |

|